An Unbiased View of Motorcycle Parts New Zealand Specialists

Table of ContentsMotorcycle Parts New Zealand Specialists - The FactsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsThings about Motorcycle Parts New Zealand SpecialistsThe Buzz on Motorcycle Parts New Zealand SpecialistsFascination About Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists Diaries4 Simple Techniques For Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Things To Know Before You Get This

Reach out to one of our experts today.CNC machining modern technology is swiftly coming to be the centerpiece of several manufacturing procedures around the world as a direct result of its lots of advantages over other methods. Additionally, the sectors that make motorcycles have jumped on board with this pattern. One of the most innovative companies are currently developing their engine components and wheels utilizing machining techniques initially established for motorcycle components.

On the other hand, the impacts of sector are the key focus of this article. Allow's get right right into it. You may be asking yourself why we make use of. It is not hard to fathom the factors that led to this result. Since we have your interest allow us clarify the rationale behind this modern-day growth in the motorbike manufacturing market.

The Motorcycle Parts New Zealand Specialists Ideas

On top of that, you have complete control over the appearance of the parts, even to the min details. Occasionally, motorcyclists might decide to beautify their experience by installing aftermarket components or customizing the bike's transformation. Once more, computer mathematical control (CNC) machining is one of the most sensible approach. Upgrades may be of any kind of kind and style you desire.

Some Ideas on Motorcycle Parts New Zealand Specialists You Need To Know

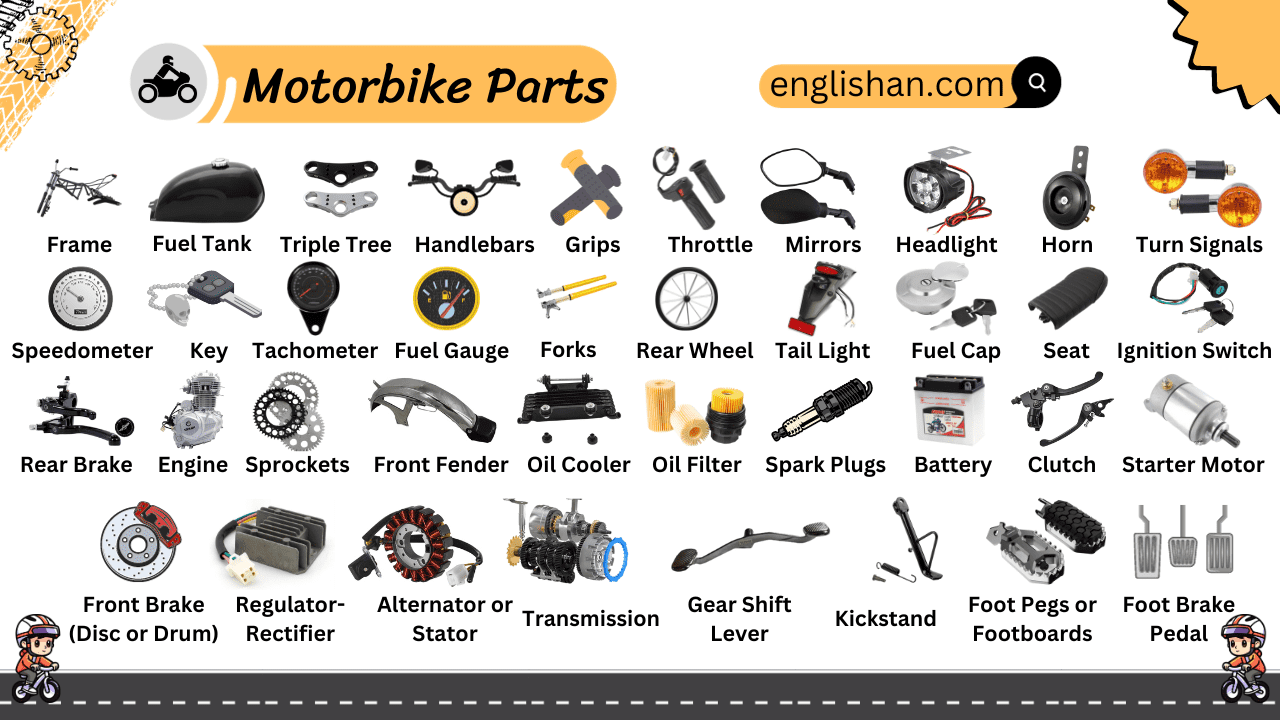

CNC machining may be used to make mostly all of a bike's metal and plastic components. To continue, we'll discuss several machined parts for motorcycles. As opposed to those on autos, wheels on motorbikes have a tendency to be more noticeable. Because of this, the bike's appearances may be improved with the ideal modification of these wheels.

Milling treatments are utilized to get the wanted degree of wheel customization. An additional facet of the bike that might be customized is the tires.

Top Guidelines Of Motorcycle Parts New Zealand Specialists

When it comes to a lorry (or a motorbike), one of the most essential component is the engine. Several individuals suggest to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be complex and require layouts with a high degree of precision.

Lighting is an additional complex facet of modification. Use just premium items, however, because these lights are crucial for the safety and security of motorcyclists and other drivers or individuals when driving, particularly during the night. Bike headlights have 3 almosts all: the light bulb, or light source, the lens, and the housing. Particularly, we tailor the lens and the housing.

Milling processes with a perfect surface would certainly cause the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of fragile materials; rather, it is constructed out of difficult polymers that can be machined right into even more complex patterns.

The 30-Second Trick For Motorcycle Parts New Zealand Specialists

They typically have fancy geometries with a wealth of min information. Motorbike manufacturers frequently cast these parts, yet only for the production of bespoke components. CNC machining is the approach of selection when producing special pieces. Machining on 5 axes in today's world is the methods whereby any style shape may be realized.

Select Runsom for your tailored motorcycle parts! We have the capacity to fabricate challenging and stylish elements making your motorbike incomparable.

Here are a few instances of steels commonly made use of in motorcycle component machining. Aluminum is the key product made use of by companies focusing on generating custom motorbike elements to produce a lot of these components. In the past, we would build our engines out of cast iron. On the other hand, aluminum is swiftly coming to be the product of choice, partly due to the fact that it is much more lightweight.

Zinc refers to an additional steel that is really light in weight and has wonderful machining qualities as a result of its high mechanical toughness. This material may be developed right into nearly any kind of shape and keeps its dimensions well. Also mission-critical components that need a high degree of accuracy might benefit from their use.

The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Another metal that sees hefty use in the production of CNC-customized elements is magnesium. It is amongst the lightest metals that are currently obtainable and has exceptional machinability attributes and toughness commensurate with its low weight. Among the drawbacks of magnesium is that its dust may quickly capture fire.

Their most typical usage in creating different bike parts is bolts, such as screws and screws. Their reduced sensitivity to oxidation and deterioration makes them ideal for visit this usage.

Little Known Questions About Motorcycle Parts New Zealand Specialists.

It appears that CNC turning and crushing are the foundational procedures. In addition, it needs keeping bars of material, most frequently plastic or metal, in placement and then turning a cutting tool to remove sections of the product as the material is turned.

These techniques are just as vital and generate components with high accuracy and constant high quality. The procedures assist boost the total top quality of the machined motorcycle components.

See This Report about Motorcycle Parts New Zealand Specialists